High capacity,

activity, and throughput.

Obstacle

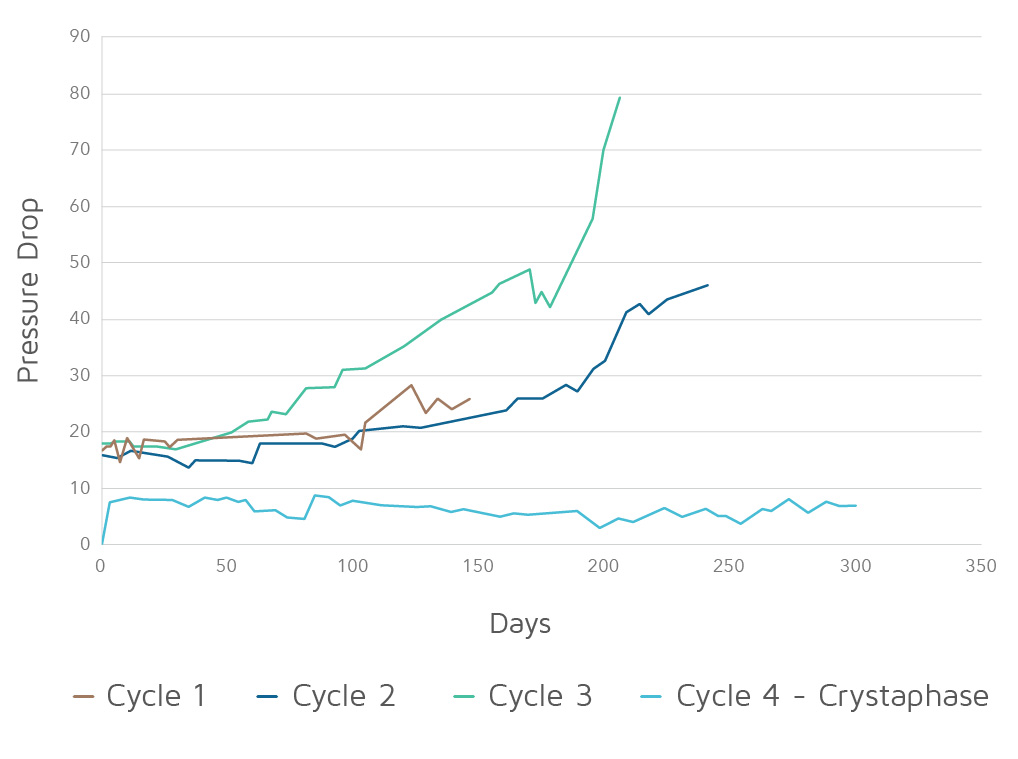

Refiners always aim for activity shutdowns. This means the catalyst has reached its natural reaction limit due to temperature-driven carbon accrual—as opposed to fouling—and has to be replaced. In this case, our customer was encountering pressure drop issues, forcing a shutdown before the catalyst was spent, the longest cycle reaching 225 days. It became such a problem that engineers had downgraded to recycled catalyst. Since the cycle was limited by pressure drop, there was no point in using the high-activity catalyst for which the reactor was designed.

Path

Crystaphase replaced 88 inches of graded material with 42 inches of CatTrap®, allowing the customer to significantly increase their catalyst volume. This increase contributed significantly to reactor activity.

Results

Our solution eliminated the pressure-drop issue, allowing the refiner to switch to the high-activity catalyst. The cycle length, which had averaged less than 200 days, shot up to 300 days, at which point the shutdown was finally due to activity instead of pressure drop. That’s a 33 percent longer production cycle on higher-activity catalyst, resulting in a 25 percent increase in daily throughput. With all these enhancements in tandem, the unit was able to process 66 percent more barrels than prior to the initial changeout.

Processed 66% more barrels.

Get more from your catalyst. Get an analysis.

The shortest path to greater throughput is a comprehensive system evaluation. Get yours.

Get your reactor analysis now.